My homebrew

I'm new here so please let me in and allow me to learn from you.

I have just brewed my first 10g test E...Now I'm a very careful person and id like to do my stuff with care and would normally pay attention to details all along the way... but despite all that my final product came out cloudy and was left unmixed. here are the steps...

As this was my second try after my first failure (my first try I couldn't even get the powder melt thoroughly due to not heating it and it was dumb coz I thought BB would be the melting agent, little did I know that it's rather just a dissolving agent) So here's the second time...

Here's my set up: I weighed 10g on my scale

I weighed 10g on my scale Placed the 10ml beaker with the powder in it on the hot plate mixer and put the thermometer stick right inside it.

Placed the 10ml beaker with the powder in it on the hot plate mixer and put the thermometer stick right inside it. Added BB and set the heating to the melting point which is 33.5 ( my hot plate will continue heating the substance up to 48 after it reaches the melting point coz the plate is still hot, which sometimes is annoying but in this case I found it convenient lol) the powder melted and it was so clear I was 100% sure it was okay to move on to the next step (oil)

Added BB and set the heating to the melting point which is 33.5 ( my hot plate will continue heating the substance up to 48 after it reaches the melting point coz the plate is still hot, which sometimes is annoying but in this case I found it convenient lol) the powder melted and it was so clear I was 100% sure it was okay to move on to the next step (oil) I measure the oil (22ml) and added to the liquid:

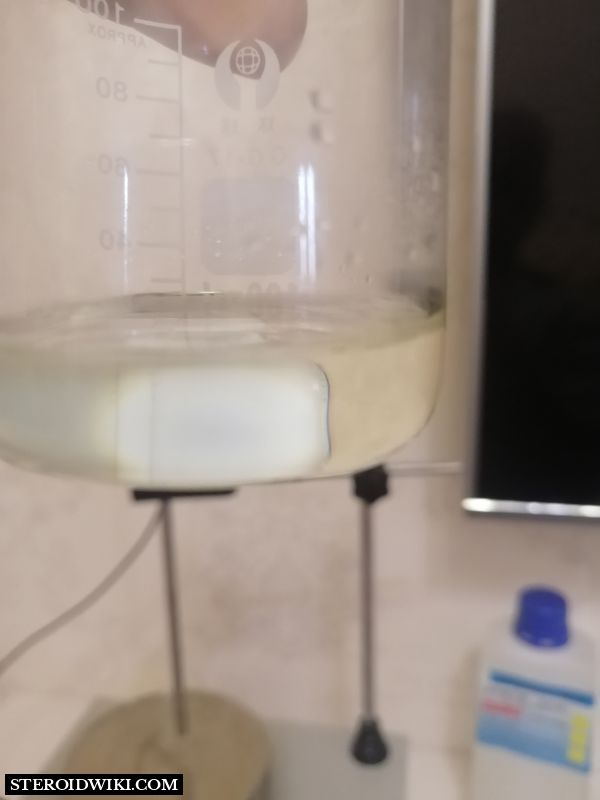

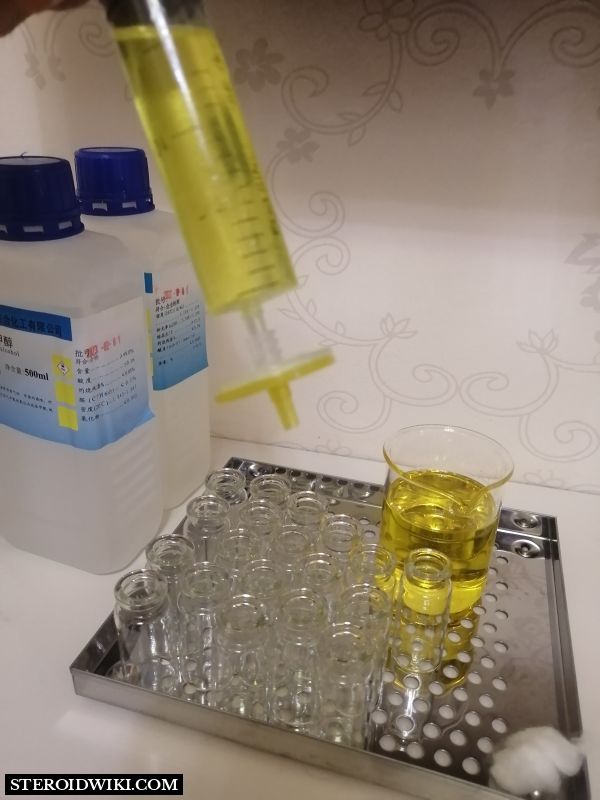

I measure the oil (22ml) and added to the liquid: I let the magnet stirrer do it's work for 10 minutes on 48c temperature before I drew up the mixture into a 20ml syringe and placing the 22um filter on the syringe:

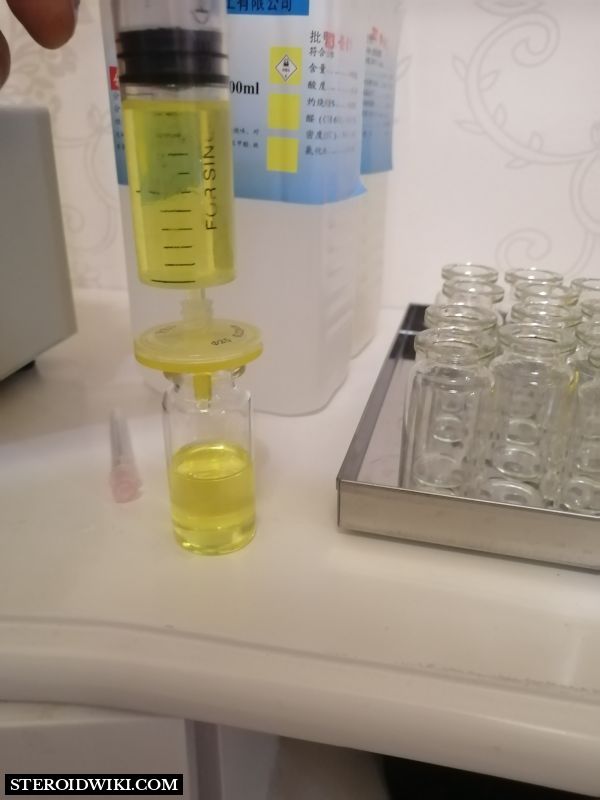

I let the magnet stirrer do it's work for 10 minutes on 48c temperature before I drew up the mixture into a 20ml syringe and placing the 22um filter on the syringe: filled up 4 vials ( I had to change to a new filter every 2 vials)

filled up 4 vials ( I had to change to a new filter every 2 vials)

Crimped them up.

Crimped them up.

They were all clear and nothing seemed unmixed until I placed them in the fridge to sit,

They were all clear and nothing seemed unmixed until I placed them in the fridge to sit,

they turned out cloudy and unmixed like half oil and half something else...

so folks where did I go wrong?

Did I have to stir longer and heat it up with higher temperature before the filtration process?

In advance: Thank you very much for your time and I appreciate you guys for letting me in and replying to this thread of mine .

Created

1 year ago

1 year ago

-

Last Reply

1 year ago

1 year ago

- 10

replies

- 1.4k

views

- 6

users

- 0

likes

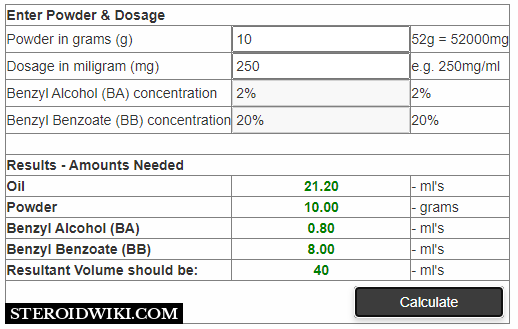

Make sure you are using the right amounts. I didn't see you mention BA or the exact amount of BB in ml's that you introduced. I am guessing it was more or less equal to the values provided below. Taken from: https://steroidwiki.com/calculators/injectable-calc.php

Taken from: https://steroidwiki.com/calculators/injectable-calc.php

I don't see any issues with your process except humidity management. You are using a digital hot plate and all the right things. Cloudiness can be due to water molecules which were present inside the vial, oil, cap or anything and condensed once you cooled the mixture down. Try heating up some water to 100 Degrees Fahrenheit (37.7 Degree Celsius) and submersing your vials under that, if the cloudiness goes away try reheating the vials inside an oven at 100 degrees F for a few minutes. Also verify that there' no residue of dirt or contaminants.

Just a few questions

- What are you using for carrier oil and is it USP Grade?

- What is the final dosage you are trying to achieve per mg/ml?

- You warmed your oil to match the temperature of the dissolved test-e before adding it?

Hello Brother,

I think if it appears to be cloudy then it is water and if it gives a milky look then it is possible that the container has bad raw or it could be contaminated.

Possibilities of cloudy steroid juice

1. Water mixed with the ingredients from using a water bath to heat during the brewing process might cause cloudiness.

2. Items don't dissolve completely. That's why a stir is necessary while brewing.

3. Issue of the ratio of BA / BB, the scale does not work well. This can't be ignored. Though these might rarely happen yet it is possible.

4. Low room temperature or big temperature difference soon after brewing it. Do not put the oil you just brewed in the fridge. Let it set at room temperature for at least 24 hours.

5. The quality of the filter that is used. Some filters would partially dissolve with BA/BB and when mixed with the oil, it causes cloudiness. And it couldn't be resolved by heating.

Solutions

1. Keep the temperature stable. Use a good-quality filter. Be more careful if you use the water batch brewing method.

2. Heat the products a little, sometimes it turns clear. Even if it turns cloudy again, it means the oil is good and can be used.

3. Reheat it to a temperature of about 200f, and hold this temperature for 10-15 minutes stirring gently. This method would be useful if the cloudiness is caused by the stream.

4. Add a tiny EO if the cloudiness is caused by partially undissolved items.

Everyone has outlined the potential issues you have.

I'm leaning towards a possible contamination when you put the rubbers on.

Looking at the pictures of the rubbers there's either water or BA sitting in the rubbers or whatever you used to clean them.

If it's water you can heat it out, if it's BA your only option is the increase the volume which will be difficult to do now for obvious reasons.

Quite a sight you've got there. I just took another look at the rubbers and they do look contaminated with water (at least).

Quoted AccessDenied; Post# 3746

Everyone has outlined the potential issues you have.

I'm leaning towards a possible contamination when you put the rubbers on.

Looking at the pictures of the rubbers there's either water or BA sitting in the rubbers or whatever you used to clean them.

If it's water you can heat it out, if it's BA your only option is the increase the volume which will be difficult to do now for obvious reasons.

He probably got a knock at the door...haha

Found the photo of the bust.

Quoted AccessDenied; Post# 3959

He probably got a knock at the door...haha